LinuxCNC is a Debian-based Linux distribution built specifically to control CNC machinery with accuracy, stability, and professional-grade reliability. Developed around Debian’s robust foundation and enhanced with real-time capabilities, it powers milling machines, lathes, 3D printers, robotic systems, laser cutters, plasma cutters, hexapods, and other automated devices. The system offers high flexibility, supports widely used hardware interfaces, and includes advanced machining features such as rigid tapping, cutter compensation, kinematics modules, and custom motion profiles. Whether for industrial workshops, educational labs, or personal maker projects, LinuxCNC stands as one of the most complete open-source CNC platforms available today.

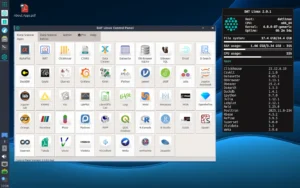

Designed for users who require deterministic performance and precise machine control, LinuxCNC boots into an Xfce desktop tailored for CNC workflows. Instead of a generic desktop environment, the interface includes a dedicated CNC menu that offers control software, configuration wizards, HAL tools, simulators, documentation, and hardware-tuning utilities. This structure ensures that users—whether engineers, machinists, or hobbyists—can begin configuring their machines quickly and efficiently. As a result, LinuxCNC serves both as an operating system and as a professional toolchain for automated fabrication.

What Makes LinuxCNC Different in the CNC Ecosystem?

Many CNC solutions depend on proprietary software, expensive licenses, or hardware restrictions that limit customization. LinuxCNC breaks those barriers by offering complete control through open-source tools. Machine builders and operators can adjust kinematics, define HAL routes, modify G-code behavior, integrate sensors, and expand motion capabilities without vendor lock-in. This level of freedom is invaluable for research laboratories, universities, custom machine manufacturers, and robotics developers that need adaptable systems instead of rigid commercial packages.

Another major advantage is the real-time performance achieved through Linux’s PREEMPT_RT or RTAI patches, depending on the installation. Real-time capabilities ensure that timing-critical CNC instructions execute without jitter or delay, enabling safe and accurate machine movements. Users benefit from dependable precision that matches or surpasses proprietary control software, making LinuxCNC a compelling alternative for both industrial and creative fabrication environments.

Key Features of LinuxCNC for Professional Machine Control

LinuxCNC incorporates several features that distinguish it as one of the most advanced open-source CNC control platforms:

- Support for a wide range of CNC machines, including mills, lathes, pick-and-place robots, laser cutters, plasma cutters, 3D printers, and hexapods.

- Real-time processing with PREEMPT_RT or RTAI to ensure deterministic machine operations.

- Advanced machining features such as rigid tapping, cutter radius compensation, threading, and multi-axis kinematics.

- Hardware Abstraction Layer (HAL) for customizing connections between hardware modules, sensors, and machine components.

- Integration with various hardware interfaces, including Mesa boards, parallel-port drivers, FPGA-based controllers, and other specialized CNC control hardware.

- Xfce desktop environment preconfigured with CNC-specific menus for quick access to tools and simulators.

- Powerful G-code interpreter with extensions for advanced motion and custom control logic.

- Built-in configuration wizards that assist users in creating machine profiles for many common CNC setups.

These features allow LinuxCNC to scale from simple hobbyist routers to advanced industrial robotics. Users gain full freedom to design workflows, build custom machines, and experiment with automation without restrictive licensing or proprietary barriers.

Performance and Real-Time Capabilities

Real-time performance is the backbone of LinuxCNC. CNC applications require precise timing to avoid errors that could damage machines or materials. LinuxCNC provides deterministic control loops that guarantee the accurate execution of each instruction. These capabilities allow machine axes to move smoothly, maintain synchronized motion, and respect safety constraints.

Depending on user requirements, LinuxCNC supports different real-time kernels: PREEMPT_RT for modern hardware and broader compatibility, or RTAI for situations that demand ultra-low-latency behavior. This flexibility lets organizations tailor their systems based on performance needs, hardware availability, and long-term maintenance plans.

User Experience and Desktop Environment

LinuxCNC uses Xfce as its desktop environment because of its stability, low resource usage, and reliability in industrial environments. The system includes a “CNC” menu category that organizes everything machine operators need: documentation, simulators, configuration editors, latency testers, wizards, HAL tools, and operational interfaces. This structure minimizes complexity and ensures a smoother learning curve for new users.

While the distribution focuses on CNC tasks, it remains a full Linux desktop. Users can browse the web, manage files, create documentation, or install additional software through Debian repositories. This combination allows LinuxCNC to serve as both a machine controller and a general-purpose workstation, reducing the need for multiple computers in workshops or labs.

Who Should Consider LinuxCNC?

LinuxCNC is ideal for machinists, engineers, researchers, robotics developers, and hobbyists who want full control over their CNC environments. It excels in scenarios where customization or experimentation is required. Educational institutions also adopt LinuxCNC because it enables students to learn machine automation using open-source tools, removing software licensing barriers that often limit access.

Because the system is Debian-based, organizations gain long-term stability, extensive hardware compatibility, and predictable updates. Combined with the freedom of open-source development, LinuxCNC becomes a cost-effective and strategic choice for both commercial and academic environments.

Why LinuxCNC Continues to Lead in Open-Source CNC Development

LinuxCNC maintains a strong position in the CNC ecosystem because it evolves alongside the open-source community. Developers, machine builders, and end users contribute enhancements, documentation, HAL modules, tutorials, and real-world testing. This collaboration ensures that the distribution keeps pace with the rapid innovation happening in fabrication, robotics, and automation.

The ability to modify everything—from motion control logic to the graphical interface—gives LinuxCNC a flexibility unmatched by proprietary alternatives. It empowers users to build CNC solutions that fit their exact requirements instead of forcing them to adapt to a vendor’s limitations.

Getting Started with LinuxCNC

LinuxCNC stands out as a reliable and customizable platform for CNC professionals, engineers, hobbyists, and educators. Its combination of a Debian base, real-time performance, and powerful tooling makes it ideal for controlling everything from small workshop routers to advanced robotic systems. If you want to explore open-source CNC control, tune your machine for precision, or build automated solutions without relying on proprietary ecosystems, LinuxCNC is an excellent starting point. To learn more about installation, documentation, and hardware support, visit the official LinuxCNC website.